The Mitsubishi DPF System

A device that vastly reduces emission of particulate matter (the main particle component of black smoke) from diesel engines of buses

A device that vastly reduces emission of particulate matter (the main particle component of black smoke) from diesel engines of buses

At Mitsubishi Motors Corp., we succeeded in eliminating most of the particulate matter emitted from diesel vehicles using the Mitsubishi DPF System, a device that automatically catches and eliminates particulate matter using a newly developed ceramic filter. Now, Mitsubishi Motors Corp. has put this system to practical use for the first time in Japan, in large commuter buses. Built to make buses both environment- and people-friendly, the Mitsubishi DPF System's development objective was to eliminate most of the particulate matter generated by diesel engines. In fact, it succeeded in removing some 80% of particulate matter, clearing long-term target values for exhaust gas. Moreover, the device even removes 100% of black smoke, making output gas invisible to the eye.To develop the Mitsubishi DPF System, we performed test runs beginning in March 1995 using Yokohama Transit Authority commuter buses, verifying practicality, performance and maintenance aspects. This fiscal year 30 buses of the YTA are outfitted with the devices, and are soon expected to be mounted on all YTA operating commuter buses.

* Particulate matter: In diesel engines, this is composed of black smoke (soot), sulfates generated by the sulfur in fuel, and organic components of unburned fuel and lubricating oil.

Overview of the Mitsubishi DPF System

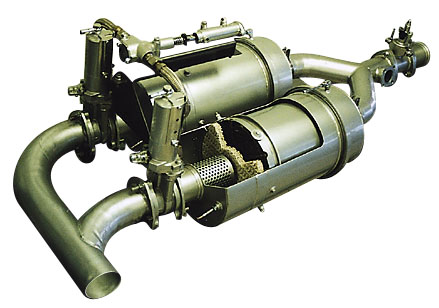

Overview of the Mitsubishi DPF SystemThe Mitsubishi DPF System traps particulate matter in a porous ceramic filter, and this accumulated particulate matter is periodically burned. By regularly exchanging two filters to continuously trap and burn particulate matter, it can be continuously collected while the bus is running.

- System Overview

This system consists of 2 filter assemblies, an exhaust gas control valve used to control the exhaust gas conducted through the filter while particulate matter is burned, an air flow sensor which detects particulate matter accumulation level, a temperature sensor, a pressure sensor and a processor that controls all of the above. The filter assemblies incorporate an electric heater which heats one end of the filter during particulate matter burning, and a heat reflector to enhance the efficiency of the electric heater.

The Mitsubishi DPF System.

- Particulate matter collection

The filters use a heat-resistant, finely porous ceramic material. These pores form parallel channels, which trap the particulate matter as it passes through. Using 2 filters, exhaust gas is passed through one filter to trap particulate matter until the accumulation level reaches a specified point, at which the exhaust gas flow is switched automatically by the switching valve to resume particulate matter collection by the other filter.

Particulate matter collection mechanism.

- Particulate matter combustion

After the filter end is heated to 600°C by the electric heater, the exhaust gas control valve is opened and part of the exhaust gas is conducted into the filter. The accumulated particulate matter inside the filter is then gradually burned over about 25 minutes by flame propagation .

Particulate matter collection and combustion process.

Effectiveness of exhaust gas cleaning

Approximately 80% of particulate matter is eliminated, achieving output levels of only half those specified in the 1988 long-term exhaust gas restriction(JIS) target. Moreover, black smoke, which accounts for most (65%) of particulate matter, is 100% eliminated, making exhaust invisible to the eye. Effectiveness of particulate matter reduction. Effectiveness of black smoke reduction.

![]() Copyright 1997 by Mitsubishi Motors Corporation.

Copyright 1997 by Mitsubishi Motors Corporation.